In this blog, we’ll compare Embroidery vs Screen Printing, exploring their histories, benefits, and uses. We’ll also have a look on factors like cost, durability, and fabric suitability.

Screen printing, or silk screening, originated in ancient China during the Song Dynasty (960-1279 AD) and spread to Japan and Europe. It gained popularity in the 20th century with the pop art movement. This technique uses a stencil to apply ink layers, ideal for vibrant, multi-colored designs.

Embroidery dates back to around 30,000 BC, with early examples in Egypt and China. It involves stitching designs onto fabric with colorful threads. Over time, embroidery evolved from hand-stitching to advanced machine techniques.

Embroidery and screen printing methods are excellent for customizing apparel, offering unique, durable designs for branding, personal expression, and fashion.

What is Screen Printing?

Screen printing, also known as silk screening. It is a popular printing technique used to transfer ink onto various materials through a mesh screen. This method is commonly applied for printing on fabrics, paper, glass, and other surfaces, making it best for a wide range of works.

It is favored for its ability to produce colorful, long-lasting designs with high color accuracy and detail. When comparing embroidery vs screen printing, screen printing often stands out for its suitability for intricate, colorful designs.

The process of screen printing begins with creating a stencil, or screen, which is a mesh stretched over a frame. The stencil is made by blocking out areas where ink should not pass through. Ink is then spread across the screen, and a squeegee is used to press the ink through the open areas of the mesh onto the printing surface below.

Each color in the design requires a separate screen, and the process is repeated for each color layer. This technique allows for precise color application and can create complex, multi-colored designs with a high level of detail.

Once printed, the material is typically cured using heat to set the ink, ensuring the screen printed logos are durable and long-lasting. This process highlights the difference between screen printing and embroidery in terms of design complexity and color usage.

8 Types of Screen Printing Inks

Understanding the different types of screen printing inks can help you choose the best one for your specific project needs.

- Plastisol

- Water-Based

- Discharge

- Gel

- High-Density

- Metallic

- Glitter

- Puff

7 Benefits of Screen Printing

Here are the 7 benefits of screen printing you can avail:

- Cost-effective for Bulk Orders

- Durable Prints and Vivid Colors

- Versatility and Quick Turnaround

- Quick Production Times

- Ideal for Intricate Designs

- Suitable for Large Designs

- High-Quality Finish

1. Cost-effective for Bulk Orders

Screen printing is a budget-friendly choice, especially when you need to print a lot of items. It’s great for those big orders where you want to save some money without sacrificing quality. So, whether you’re printing a bunch of shirts for an event or promotional items for your business, screen printing has got you covered without breaking the bank.

2. Durable Prints and Vivid Colors

With screen printing, you get prints that can take a beating and still look great. The colors are bold and vibrant, and the prints hold up well over time, even after multiple washes or being out in the sun. So, whether it’s shirts, banners, or other items, you can trust that your designs will stay looking sharp.

3. Versatility and Quick Turnaround

Screen printing is one of the best printing methods—it works on all sorts of materials, from fabric to paper to plastic. Plus, it’s super quick, which is perfect when you’re on a tight deadline or need to churn out a bunch of items fast. So, whether you’re printing intricate designs or large-scale projects, screen printing gets the job done swiftly and with style.

4. Quick Production Times

When time is of the essence, screen printing is your go-to solution. Its streamlined process allows for quick turnaround times, perfect for those last-minute orders or urgent projects. Whether you need a small batch or a large quantity printed, screen printing ensures your items are ready when you need them.

5. Ideal for Intricate Designs

Screen printing isn’t just for simple designs—it excels at bringing intricate designs to life. The fine details and intricate patterns are reproduced with precision, resulting in stunning finished products. So, whether you have a complex logo or a detailed illustration, screen printing can capture every nuance with clarity and accuracy.

6. Suitable for Large Designs

Got a big design that needs to make a bold statement? Screen printing is up to the task. Its ability to handle large designs means you can go as big and bold as you want, whether it’s for banners, posters, or oversized apparel. With screen printing, your larger-than-life designs will command attention and make a lasting impression.

7. High-Quality Finish

Quality is paramount with screen printing. Each print boasts a professional, high-quality finish that reflects the care and precision put into the process. The colors are vibrant, the lines are crisp, and the overall result is nothing short of impressive. With screen printing, you can trust that your finished products will exceed expectations every time.

Use Cases for Screen Printing

Screen printing works best when producing personalized clothing such as wholesale t-shirts, men polo shirts, and sweatshirts & hoodies. Custom clothing, advertising, posters, and promotional products are among the most common uses.

Screen printed logos are used extensively in many industries. For example, the fashion industry uses screen printing to create colorful designs on apparel, bags and sports teams frequently choose screen printed jerseys over stitched counterparts for their uniforms. Businesses also use screen printing to create promotional stuff that makes their logo stand out with vibrant, durable colors. The benefits of screen printing over embroidery for certain uses are highlighted by this method’s adaptability, which makes it the preferred option for many branding and marketing requirements.

What is Embroidery?

Embroidery is a technique that involves stitching designs onto fabric using a needle and thread. This method has been around for centuries and is known for its durability and high-quality finish. When comparing embroidery vs screen printing, many people prefer embroidery for its elegant and professional appearance, especially for corporate logos and workwear.

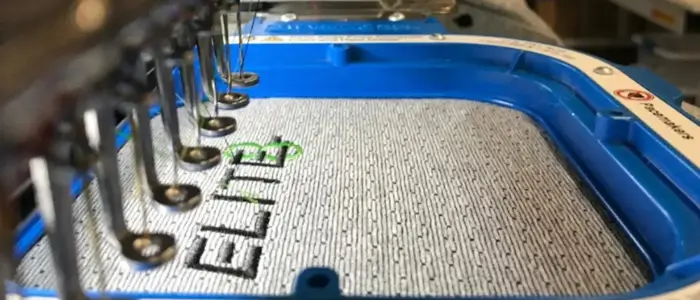

The process of embroidery starts with a design that is digitized into a format that an embroidery machine can read. This digital design guides the machine on where to stitch and which colors to use.

The fabric is then placed in a hoop to keep it taut, and the machine stitches the design onto the fabric using various types of threads. Embroidery uses threads to create a textured, three-dimensional appearance, as opposed to screen printing, which applies ink to the surface.

This makes embroidered logos Vs printed ones stand out due to their depth and intricate detailing. Embroidery is a highly suitable technique for producing long-lasting and excellent patterns on various items such as women polo shirts, fleece jackets, and headwear. It adds a luxurious and sophisticated aspect to any piece of clothing.

5 Types of Embroidery Threads

Choosing the right embroidery thread is crucial for achieving the desired look and feel of your embroidered designs.

- Polyester

- Rayon

- Cotton

- Silk

- Metallic

5 Benefits of Embroidery

1. Durability

Embroidered designs exhibit exceptional durability and can endure numerous washes without experiencing any fading or fraying.

2. Luxurious Look

Embroidery imparts an elegant and polished look, making it well-suited for corporate attire and premium branding.

3. Versatility

Applicable to an extensive variety of textiles and items, including polo shirts, hats, and jackets.

4. Professional Appearance

Embroidery offers a refined and elegant appearance, making it ideal for showcasing company logos and product names.

5. Perceived Value

When clothes have special designs sewn just for you, people think they’re more special. This makes the brand look better and makes customers happier.

Use Cases for Embroidery

Embroidery is best used for items that require a professional and polished look, such as blank t-shirts, high visibility jackets, and work shirts. This method is popular for creating embroidered logos on clothing, giving a sense of luxury and quality.

Industries like hospitality, corporate, and sports often utilize custom embroidery services for branding and identification purposes. For example, a hotel might have staff uniforms with embroidery to showcase the company logo elegantly.

Sports teams often choose embroidered uniforms and jackets for their durability and high-quality appearance. Compared to screen printing, embroidery is often the preferred choice for items that need to convey professionalism and sophistication, making it a go-to option for many businesses.

Comparing Screen Printing and Embroidery (Durability, Cost, and Appearance)

When deciding between screen print Vs embroidery, it’s essential to consider various factors such as durability, cost, and appearance. Each method has its unique benefits and ideal use cases, which can help you determine the best option for your specific needs.

Durability Comparison of Screen Print Vs Embroidery

| Factors | Screen Printing | Embroidery |

| Overall Durability | Screen printing is less durable than embroidery, but can still be a viable option for items that won’t be subjected to frequent washing or harsh conditions. | Embroidery offers superior durability, making it a better choice for items that will be washed frequently or used in demanding environments. |

| Longevity | Screen prints can fade over time, especially when exposed to sunlight and frequent washing. The quality of the ink and the fabric used also play a role in longevity. | Embroidery is generally more durable and can withstand repeated washing and wear. The thread used in embroidery is typically more resistant to fading and wear than ink. |

| Best Practices for Maintenance | Wash inside out in cold water, air dry, avoid bleach and iron directly on the print. | Wash inside out in cold water, air dry, avoid bleach and iron directly on the embroidery. |

Cost Analysis Between Screen Print and Embroidery

| Factors | Screen Printing | Embroidery |

| Cost Factors in per piece | Lower, decreases significantly with quantity | Higher, due to time-intensive process |

| Cost Factors in Bulk | Very low, highly economical for large orders | Higher, less reduction in per unit cost |

Appearance and Aesthetics (Which is better?)

| Features | Screen Printing | Embroidery | ||

|

|

Luxurious, textured finish |

Complexity of Design Between embroidery or screen printing

| Factors |

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

Screen printing: Struggles with small text Embroidery: Limited to fabric texture |

Suitability for Different Fabrics in Between Embroidery and Screen Printing

| Factors |

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

Screen printing: Works on most fabrics Embroidery: Limited on sheer fabrics |

Embroidery vs Screen printing – What’s Better for Business Purpose

Products that feature personalized embroidery are often perceived as having a greater worth, which in turn improves the reputation of the brand and increases customer satisfaction.

Marketing Potential

Businesses can benefit greatly from the marketing potential of both approaches. For attention-grabbing, big, bold designs, screen printing works well for promotional t-shirts, banners, and signage. Conversely, embroidery offers a more sophisticated and polished appearance, which makes it ideal for premium merchandise, uniforms, and business wear.

Brand Image

The choice between screen printing and embroidery can significantly impact a brand’s image. Embroidery conveys a sense of quality, craftsmanship, and attention to detail, which can enhance a brand’s reputation for excellence. Conversely, screen printing offers a more casual and vibrant aesthetic, which may be better suited for brands aiming to appeal to a younger demographic.

Customer Preferences

When it comes to customers, most of them ask how long screen printing lasts. Understanding customer preferences is important when choosing between both methods. Some customers may prefer the bold and eye-catching designs produced by screen printing, while others may appreciate the sophistication and durability of embroidery. It’s essential to consider your target audience and their preferences when selecting the best option for your business.

What are the Pros and Cons of Embroidery Printing?

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

|

|||

|

❌ Limited color blending options |

Common Misconceptions About Screen Printing Vs Embroidery

Myths About Screen Printing

- Screen printing is only suitable for large orders.

- Screen prints fade quickly.

- Screen printing is not environmentally friendly.

Myths About Embroidery

- Embroidery is too expensive for small businesses.

- Embroidery is limited to basic designs.

- Embroidery is not suitable for modern branding.

Clarifying Facts

- Screen printing can be cost-effective for small orders with the right provider.

- Embroidery offers versatility in design, including intricate logos and text.

- Both embroidered Vs screen printing can be eco-friendly with the use of sustainable materials and practices.

Future of Embroidery and Screen Printing

Future of Embroidery

The future of embroidery holds new developments in the always changing fields of textiles and branding. Technological developments will likely lead to more productive embroidery machines that can create complex designs at higher speeds without sacrificing quality. Experts in the field predict that the market for embroidery will expand due to a spike in consumer demand for individualized and customizable goods. Businesses that want to stay ahead of the curve in this fast-paced industry should consider adopting sustainable practices, investing in the latest technology, and pursuing innovative partnerships with manufacturers and designers.

Future of Screen Printing

The future prospects for screen printing are quite great as long as technology keeps developing. More environmentally friendly practices and improved print quality will come with the arrival of innovations like digital screen printing and eco-friendly inks. Industry forecasts predict a move toward digitalization and automation, which will streamline production procedures and shorten lead times. Businesses should make research and development investments, investigate novel materials and methods, and adjust to changing consumer preferences for customizable and environmentally friendly products in order to keep up with these changes.

Embroidery vs Screen Printing – FAQs

How much does embroidery cost?

The cost of embroidery can vary based on several factors including the complexity of the design, the number of colors used, and the number of items being embroidered. Typically, custom embroidery pricing is calculated per stitch and can range from $1 to $5 per 1,000 stitches. For a more precise quote, it’s best to contact a custom embroidery service with your design details.

How much does Screen Printing cost?

Screen printing costs depend on the number of colors in the design, the number of items to be printed, and the complexity of the artwork. Generally, screen printing logos can range from $5 to $10 per item for simple, single-color designs, with prices increasing for more complex, multi-color prints. Bulk orders often reduce the cost per item.

How long does screen printing last?

Screen printing is known for its durability. With proper care, screen printed designs can last for many years without significant fading. Quality ink and fabric selection can further enhance the longevity of screen printed shirts and other items.

Conclusion

Embroidery and screen printing are two great ways to make plain clothes look unique. Embroidery uses thread to create designs on fabric, giving a fancy and durable look. It works best on thicker fabrics and has been used for a long time. Screen printing, on the other hand, uses a stencil to apply ink, allowing for bright and colorful designs. This method is versatile and can be used on many different items, not just clothes.

So, which one is better, when it is embroidery vs screen printing? Well, it depends! If you want a high-quality design that lasts a long time on thicker clothes, go with embroidery. If you need a fun, colorful design for promotions or lighter fabrics, screen printing is the way to go. Both methods add a special touch to your clothes, making them unique and personal.

Published on:

June 12, 2024