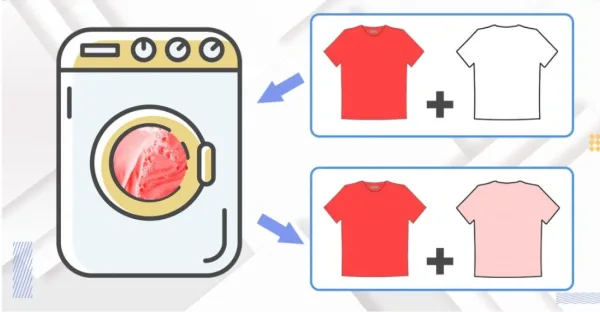

Dye migration is the silent killer of custom apparel businesses. You spend hours perfecting a design, tweaking the artwork, and setting up your press, only to find that your crisp white ink has turned a dull pink or muddy grey 24 hours later. In the industry, we call this “bleeding,” and if you are operating in the professional printing space, mastering the art of controlling it is what separates the veterans from the amateurs.

What is Dye Migration?

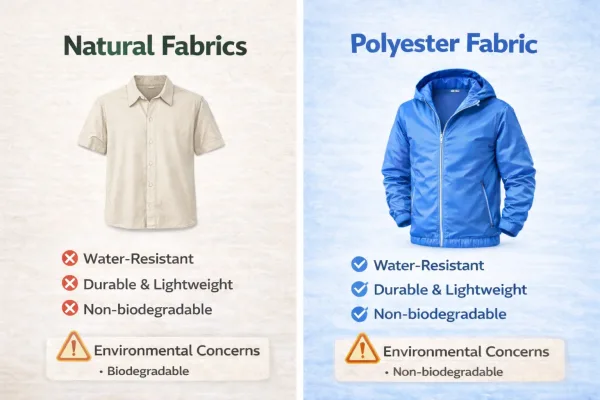

To fight dye migration, you must first understand your enemy. Unlike natural fibres like cotton, polyester is a synthetic polymer dyed using disperse dyes. These dyes do not chemically bond to the fibre in the same way reactive dyes do; instead, they are held within the polyester structure.

When you subject polyester to heat specifically during the curing process a phenomenon called sublimation occurs. At temperatures typically ranging between 300°F and 330°F, the solid dye particles in the fabric turn into a gas. This gas seeks an escape route, and if you have a layer of wet or semi-cured ink sitting on top, the gas bleeds into the ink.

The Delayed Reaction

The most frustrating part of dye migration is that it isn’t always immediate. You might pull a shirt off the dryer and it looks perfect. However, as the garment sits in a box or a stack, the residual heat continues the sublimation process. By the time it reaches your customer, the colour shift has occurred. This is why sourcing high-quality wholesale polyester t-shirts is your first line of defence.

Why Polyester is Unique (and Tricky)

Polyester is hydrophobic, meaning it repels water. This makes it great for performance tech tees and moisture-wicking gear, but it makes the dyeing process intense. Because the fabric is “plastic-like,” it requires high pressure and heat to accept colour. If the fabric wasn’t “set” correctly at the textile mill, the dye remains “loose” and ready to migrate at the first sign of heat.

When you are dealing with custom polyester hoodies or heavy outerwear, the density of the fabric means there is even more dye available to migrate. According to textile chemistry standards, the molecular structure of synthetic fibers expands under heat, which is exactly when the dye molecules become mobile.

Common Culprits: The “Bleeding” Variables

Before we get into the solutions, let’s identify the variables that increase your risk of migration:

- Excessive Curing Heat: If your conveyor dryer is set too high, you are essentially “cooking” the dye out of the shirt.

- Low-Quality Fabric Blanks: Budget-friendly blanks often skip the final “scouring” or “setting” stages in manufacturing, leaving excess dye on the surface.

- Ink Saturation: Printing a thick, heavy layer of white ink creates a thermal mass that holds heat longer, giving the dye more time to sublimate.

- Improper Stacking: Catching hot shirts at the end of the dryer and stacking them high traps heat. The shirts in the middle of the stack stay hot for minutes, leading to massive migration.

5 Strategies to Stop Migration

1. The Power of Premium Blanks

You cannot out-print a bad garment. High-quality wholesale blank t-shirts are treated with better chemicals and go through more rigorous rinsing cycles. When you browse the polyester performance wear section at The Apparel Factory, you are looking at garments designed to withstand the rigors of professional decoration. Using Cationic dyed polyester is a pro secret; these fabrics are dyed at a lower temperature and are much more stable during the printing process.

2. Utilizing Low-Bleed (LB) Inks

Never use standard plastisol on 100% polyester. You need specialized Low-Bleed (LB) Inks. These inks are formulated with “blocker” agents usually high-opacity pigments and chemicals that act as a shield. They are designed to stay “closed” so the gas cannot penetrate the surface of the print.

3. The “Carbon” or “Grey Blocker” Underbase

For the most difficult fabrics (like red or maroon 100% polyester), even LB White ink might fail. This is where the Grey Blocker comes in.

- Layer 1: Print a Grey Blocker (which contains carbon particles that trap gas).

- Layer 2: Flash cure.

- Layer 3: Print your White or highlight colour. The grey layer acts as a “filter,” catching the gas before it hits your bright top colours. This is a standard procedure for high-end custom screen printing services.

4. Low-Cure Technology: The Game Changer

The industry is moving toward Low-Cure Inks. While traditional inks need 320°F to cure, low-cure inks can fuse at 270°F to 285°F. Since most polyester dyes don’t start to sublimate until they hit 300°F, staying at 280°F keeps the dye in a solid state. This drastically reduces the risk of bleeding and also prevents “fabric scorching” those shiny marks you sometimes see on heat-pressed polyester.

5. Managing the “Cool Down”

Your job isn’t done when the shirt leaves the dryer. To prevent migration in the box, ensure your shop has a cooling station.

- Avoid “nesting” or stacking hot shirts.

- Use a fan at the end of the belt to bring the garment temperature down quickly.

- If you are doing custom hoodies, give them extra space to breathe as they hold more heat than t-shirts.

The “Cold Peel” and Heat Press Considerations

If you are using heat transfers or vinyl instead of screen printing, the risks are the same. When applying designs to activewear blanks, always use a “Low-Temp” adhesive. If your heat press is set to 350°F for 15 seconds, you are almost guaranteed to see migration. Look for materials that apply at 275°F for shorter durations to keep the fabric cool.

Quality Control: The 24-Hour Test

Every pro shop should have a testing protocol. Before you run a 500-piece order of custom jackets, perform a “Ghosting Test.”

- Print a sample.

- Cure it at your planned settings.

- Place a white piece of scrap fabric over the print.

- Apply a heavy weight and leave it in a warm area for 24 hours. If the white scrap or the print shows no color change after a day, your settings are dialled in. This methodology aligns with ISO fastness testing for textile color stability.

Why Wholesale Sourcing Matters

In the world of wholesale apparel, you get what you pay for. Choosing a supplier that understands the technical needs of a printer is vital. At The Apparel Factory, we don’t just sell clothes; we provide the foundation for your business. Our inventory of bulk polyester shirts and blends is tested for printability, ensuring that you spend less time troubleshooting migration and more time growing your brand.

Whether you are catering to a local gym with performance tech tees or a corporate client needing custom screen printing, your fabric choice is the most important decision you’ll make.

Conclusion:

Mastering polyester printing is a badge of honour. While other shops might shy away from 100% polyester due to bleeding issues, your ability to provide clean, vibrant prints will allow you to charge a premium. By combining high-quality wholesale blanks from a trusted partner like The Apparel Factory with low-cure ink technology and proper temperature management, you can conquer any fabric.

Stop fearing the “bleed” and start embracing the durability and performance of polyester. With the right chemistry and the right supplier, your prints will stand the test of time.

Frequently Asked Questions

Published on:

February 9, 2026